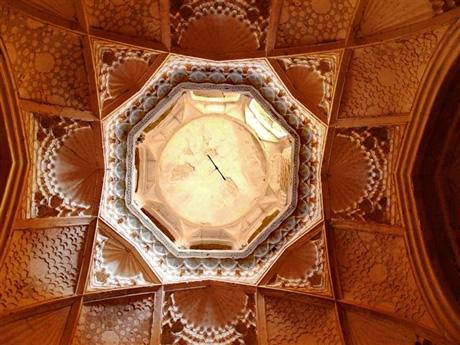

Muqarnas

Muqarnas, sometimes called ‘stalactite vaulting’, are a three-dimensional form of architectural decoration of domes, niches and the underside of vaults. For the craftsmen-constructors, they require the application of detailed geometric principles; for the viewer, they allow infinitely imaginative reviewing. This Timurid muqarnas – from the Khargird madrese in NE Iran – has additional painted stucco …